Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product Introduction | |

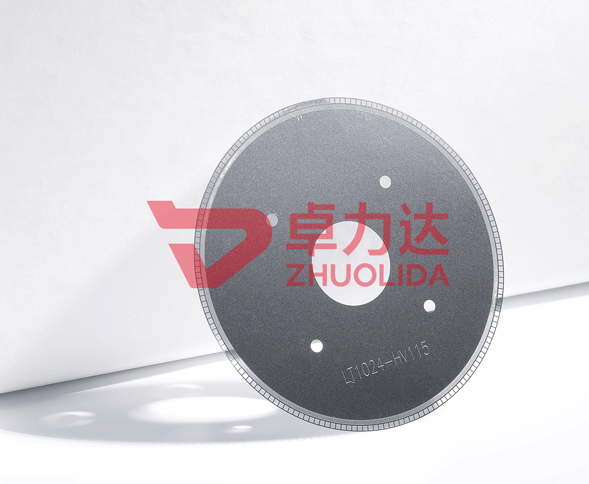

Product name: | |

Product Introduction: | Stainless steel code discs are key components in equipment that encodes or converts signals or data into signals that can be used for communication, transmission, and storage. |

Product usage: | Stainless steel code valve disc is suitable for chemical, oil and gas, food and beverage, pharmaceutical, water treatment and power industries. |

Etching process: | Opening → Cleaning the plate → Dry film or coating → Drying → Exposure → Development → Drying → Etching → Release → Detection and packaging --- finished product shipment |

我们的优势 | |

1、As of 2025, we have been engaged in the field of etching for more than 20 years, and have been committed to technological innovation, research and development, production and sales of stainless steel pallets in the high-end market. Determined to become a century-old enterprise in China's etching industry! | |

2、The company has successively passed ISO9001: 2008 quality management certification and ISO14001: 2004 environmental management system. In 2016, it passed ISO / TS 16949 certification and high-tech enterprise certification of the automotive industry. | |

3、The company has advanced processing equipment and technology, to ensure the high precision and consistency of the valve disc, improve product performance. | |

4、Stainless steel materials can be recycled, in line with environmental requirements, help the company to practice sustainable development concept. | |

5、We can make stainless steel code discs with a thickness of 0.02 MM and an etched size of 800 * 700mm. Depending on the product, the accuracy can reach +/- 0.005mm. | |

01

High strength and wear resistance: with good mechanical properties, suitable for high pressure, high wear environment.

02

Strong corrosion resistance: stainless steel material can effectively resist corrosion and extend service life.

03

Excellent sealing performance: the design is precise to ensure good sealing effect and prevent leakage.

04

Easy maintenance: Simple structure, easy to install and daily maintenance.

Zhuo Lida can use a roll-to-roll exposure machine, which can be produced in large quantities, up to 1,000 square meters per day. It can also be put into production in a semi-automatic manner for small batches of diversified stainless steel code discs, saving related operating costs and saving costs for customers. The stainless steel code discs we produce have no burrs, pressure points, no deformation of the product, do not change the material properties, and do not affect the function of the product. If you are looking for a stainless steel pallet manufacturer, please contact us. All staff of Zhuolida will serve you wholeheartedly.