Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

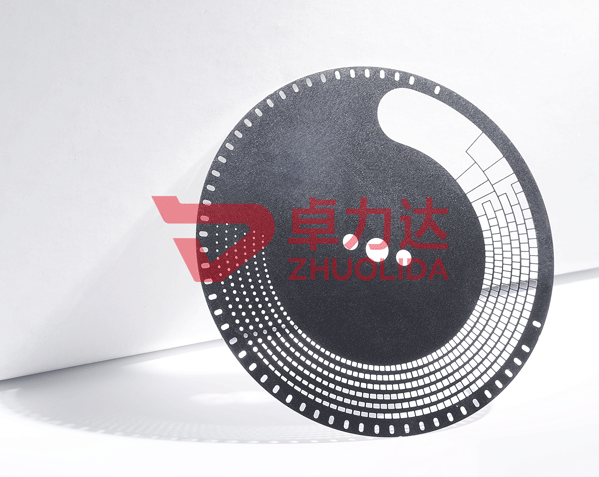

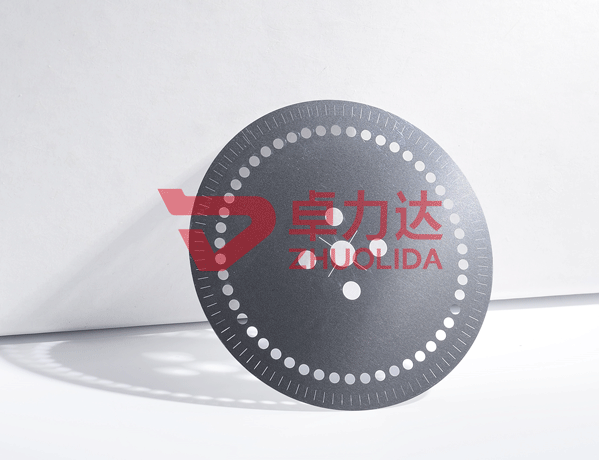

The diaphragm of various apertures produced by the chemical etching process can achieve flatness of 0.02mm, small apertures can be processed to 0.05mm, high precision can reach +/- 0.005mm, and the perfect roundness of the holes can also help customers Blackening and matting.

02

The function of the diaphragm is to transmit light, and of course, to limit the size of the beam and the imaging effect while the light passes. This requires the holes on the diaphragm to be vertical, the walls of the holes to be smooth, the roundness of the holes to be high, the aperture tolerance to be strict, and the overall flatness of the product to be high. In summary, the production of diaphragms is closely related to the equipment and technology of the factory. At present, many spectrometer manufacturers and manufacturers using diaphragms have purchased them abroad. The process is chemical etching. Because the chemical etching process can meet all the requirements of the diaphragm, it can achieve the effects of accurate aperture data, vertical hole walls, and so on.

There are a lot of optical instruments currently in use, often because the diaphragm is damaged, making the instrument unusable. However, the manufacture of diaphragms is too thin, and it is easy to produce shortcomings such as warping, edging, and burrs when using shearing or punching methods. The diaphragm is manufactured by the etching method. This method is simple and can meet the quality requirements. After 20 years of development and accumulation, Zhuolida has a variety of chemical etching equipment and is engaged in the etching of various shapes of diaphragms. If you want to find a diaphragm etching manufacturer, please contact us. You serve.