Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product introduction | |

Product name: | |

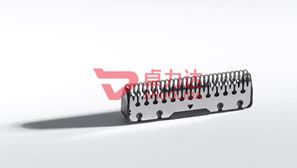

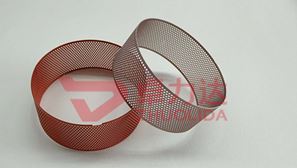

Product description: | A microporous filter is a device that uses a microporous filter membrane to filter, which is mainly used to separate particles and microorganisms in liquids or gases. |

Product usage: | Micro-hole filter processing is mainly used in electronics, machinery, automotive, hardware, electrical appliances and other industries. |

Etching process: | Material opening → cleaning plate → dry film or coating → drying → exposure → development → drying → etching → stripping → detection of packaging -- finished product shipment. |

Our strengths | |

1. Till 2025, we have been engaged in the field of etching for more than 20 years. In 2015, the company invested in the construction of a new industrial park in nantong.Aspire to become China's etching industry hundred year enterprise! | |

2. The company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the company has passed ISO/TS 16949 certification and high-tech enterprise certification in the automotive industry, and obtained a number of intellectual property patent certificates.Technology innovation and talent training are the driving force for enterprise development. Zolida has been focusing on technology research and development, and has cooperated with many universities, such as nanjing university of aeronautics and astronautics. It has set up laboratories, hired and trained high-tech talents, and is a benchmark enterprise in the etching industry. | |

3. As a member of PCMI, the world etching association, the company can share new information and equipment of the global etching industry. | |

4. Several etching production lines have been introduced, and the company has an automatic adding system and regeneration system for potions. While developing, the company also pays attention to environmental protection.The company aspires to become an environmental protection enterprise, green enterprise. | |

5. We can make micro-hole filter with thickness of 0.02mm and etching size of 800*700mm. The precision can reach +/-0.005mm according to the product.Strive for high precision, high standards for survival, development, to benefit. | |

01

High precision filtration: The filtration accuracy is between 0.1 and 5 microns, effectively removing bacteria, viruses and other small particles.

02

Easy maintenance: Removable design for easy cleaning and replacement of filters.

03

Strong adaptability: different pore sizes and materials can be customized.

04

Strong adaptability: different pore sizes and materials can be customized.

The size, width, break point and concave point of the meshes processed by micro-hole filter will affect the accuracy of products and the sensitivity of filtration in the future.Our purification workshop, at all levels, is the requirement of processing such products have, of course, we also have several imported stainless steel processing production line, ensure product etching processing precision of the data, perfect quality control system, let the unqualified products do not flow to the customer, ZhuoLiDa with many fortune 500 companies, the material is given priority to with import company use, can carry on the etching process for a variety of different materials, according to the thickness of the material, aperture can be 0.05 mm, flatness remain below 0.02 mm, can be smaller tolerance to + / - 0.0075 mm,Service starts from the communication of the soul, which is the sincere commitment of zhuolida people to every customer.