Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product introduction | |

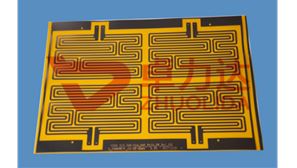

Product name: | Microchannel cold plate |

Product description: | Microchannel, also known as microchannel cold plate, is a heat exchanger with a channel diameter of 10 to 1000um.Its internal flat tube has dozens of fine flow channels, which are connected with the circular manifold at both ends of the flat tube. |

Product usage: | Microchannel cold plate is widely used in electronic components, automotive, aerospace, micro-chiller and energy fields. |

After-sales service: | Precision detection of secondary element and imaging instrument, 24-hour service hotline 0513-81601666. We are a high-end and precise etching factory, and we are responsible for the after-sales of all our products.Whether it is service attitude, or product quality, communication about product design, sales quality of service, can be directly communicated.Our factory has a quality control team, quick response mechanism, for customer complaints, within 24 hours to reply.Propose corrective measures within 48 hours and complete delivery within three days. |

Our strengths | |

1. Till 2018, we have been engaged in the field of etching for 19 years. In 2015, the company invested in the construction of a new industrial park in nantong. | |

2. The group company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the group company has passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained multiple property rights and patents.Zolida has been focusing on technology research and development, and a number of cooperation, laboratory and external employment and training of high-tech talents, is a benchmark enterprise in the etching industry. | |

3. As a member of PCMI, the world etching association, the company can share new information and equipment of the global etching industry. | |

4. The company has introduced several etching production lines and vacuum diffusion welding equipment, and has an automatic adding system and regeneration system for potions. While developing, the company also pays attention to environmental protection.The company aspires to become an environmental protection enterprise, green enterprise. | |

5. Microchannel cold plates were all produced in foreign countries before. Zolida introduced high-end technology, integrated etching and diffusion welding, and took the lead in the research in the field of microchannel, which can provide customers with an overall solution for microchannel heat exchangers. | |

6. Shenzhen zhuolida, kunshan zhuolida and nantong zhuolida three production bases, with a comprehensive area of more than 40,000 square meters.Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions.The first floor of building 1, zhuolida, nantong is the electrophoresis workshop.The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the requirements of production capacity and precision of various products.The fourth floor is the vacuum diffusion welding workshop.Building 2 is an electroplating industry. | |

01

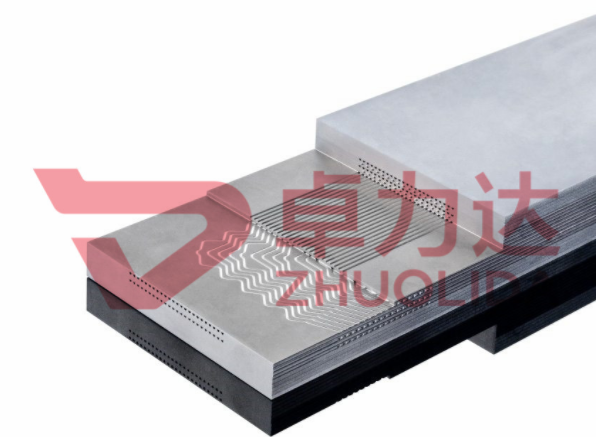

Microchannel cold plate is composed of several layers of metal sheet of different thickness with no burr or bump on the surface after etching, applying appropriate pressure and temperature in the vacuum state, and combining with reasonable time.The honeycomb section formed after the bonding between the metal surfaces can make the high-pressure fluid pass through the micro channel without leakage. The tensile strength of the product after the connection is not lower than the tensile strength of the original plate.The channel equivalent diameter of the microchannel heat exchanger is between 10 m and 1000 m.Because of its advantages of high compactness, small volume and high pressure resistance, it is widely used in laser cooling, precision instruments, medical equipment, aerospace and other occasions.

02

Microchannel cold plate is made of multi-layer stainless steel 316L lamination, vacuum diffusion and processing. The material is food grade, with high processing accuracy, rapid heat exchange and small volume.At present, the main welding methods are brazing, fusion and diffusion welding.

03

Application of micro-channel cold plate in the field of new energy vehicles:

①When the battery temperature is high, effective heat dissipation, to prevent the occurrence of thermal out of control accidents;②Preheat the battery when the battery temperature is low, improve the battery temperature, to ensure the reliability of charging and discharging performance at low temperature;③reduce the temperature difference in the battery pack, inhibit the formation of local hot zone, prevent the battery from rapidly decaying at high temperature, and reduce the overall battery life.

04

Application of microchannel cold plate in the field of electronic appliances:

There are many electronic components on electronic appliances. During the use of electronic appliances, electronic components will generate a lot of heat. If the heat cannot be taken away in time, the normal use of equipment will be greatly affected.Because of the characteristics of small volume, light weight and large heat exchange, microchannel cold plate is suitable for cooling electronic components in many aspects.

If you need microchannel cold plate processing please contact us zhuolida company, zhuolida will be dedicated to serve you.