Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

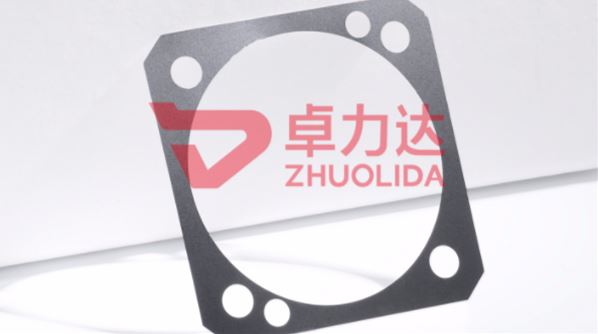

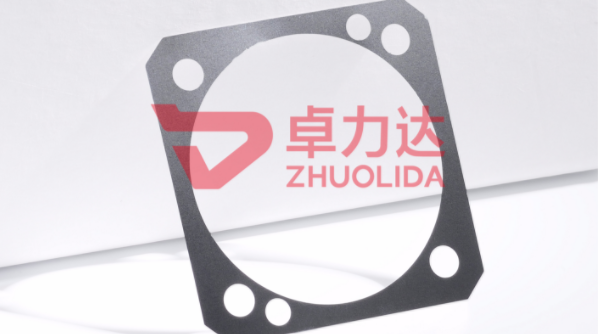

Precision gasket material for the original imported stainless steel and high carbon steel and brass three materials through heat treatment grinding processing, with high precision, strong tension, good finish, toughness, not easy to break the characteristics.The high carbon steel material has a certain degree of elasticity, stainless steel has a very high toughness.

02

The precision gasket material is made of imported stainless steel, high carbon steel and brass after heat treatment and fine grinding. It has the characteristics of high precision, strong tension, good finish, toughness and not easy to break. The material of high carbon steel has certain elasticity, and stainless steel has very high toughness.

03

High precision, strong pull, good finish, toughness, not easy to break.The high carbon steel material has a certain degree of elasticity, stainless steel has a very high toughness.Widely used in precision mold manufacturing, precision machinery, hardware parts, mechanical parts, measurement, stamping parts, hardware manufacturing, electronic instruments.Mold maintenance, mold measurement clearance and mechanical aging due to shaking, swing and instability phenomenon, can use this product to solve the maintenance problem.

04

Equipment is the basis of product quality and capacity guarantee. Zolida has a complete set of excellent imported and domestic equipment, and has formed a good strategic partnership with equipment manufacturers.Stable high-precision equipment provides us with good quality and production capacity guarantee of precision gasket.

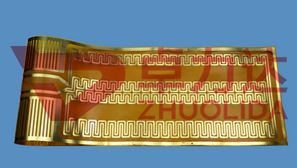

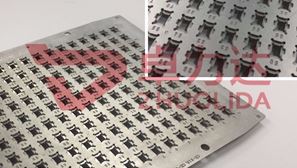

In general, produce precision gasket products we first think of is produced by stamping process, but the stamping process to produce shims have burr and oil is difficult to clean, the problem is the product precision and deformation problem, because generally shim is use stainless steel or brass data by chemical etching process or stamping process,Generally have the thickness of 0.025 mm, 0.03 mm, 0.04 mm, 0.05 mm, 0.06 mm, 0.07 mm, 0.08 mm, 0.10 mm, 0.12 mm, 0.15 mm, 0.18 mm, 0.2 mm, 0.25 mm, 0.3 mm thickness, etc.

The thickness produced by stamping process is generally more than 0.1mm gasket, for the less than 0.1mm precision gasket is generally selected chemical etching process to produce.The precision gasket made by chemical etching has high precision, high efficiency and high flatness.Zolida has a number of precision gasket etching equipment, quality, time, affordable, welcome to contact us.