Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product Introduction | |

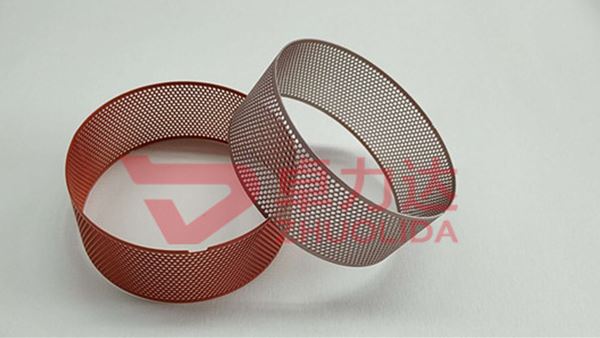

Product name: | Seamless welding |

Welding principle: | When welding, a heat source (such as an arc, laser, or gas flame) is used to heat the metal edges to a molten state and then let them naturally fuse. After cooling, the metal solidifies, forming a seamless connection. |

Product usage: | Seamless welding is widely used in automobile manufacturing, aerospace, construction, home appliances. |

After-sales service: | The quadratic element, the imaging instrument precision detection, the 24-hour service hotline 0513-81601666. Responsible for all the products of our company. Whether it is service attitude, or product quality, early communication about product design, sales quality of service, can be directly communicated. Our factory has a quality control team, a quick response mechanism, for customer complaints, within 24 hours to reply. Propose corrective measures within 48 hours and complete finished products delivery within three days. |

Our strengths | |

1、Till 2025, we have been engaged in the field of etching for more than 20 years. In 2015, the company invested in the construction of a new industrial park in nantong, learned from the successful experience of shenzhen and kunshan branch, and committed to technical innovation, r&d, production and sales of seamless welding products in the middle and high-end market. | |

2、We utilize state-of-the-art welding equipment, including laser welding systems and automated TIG welding machines, to achieve unparalleled precision and quality. | |

3、Every product undergoes rigorous testing and inspection to ensure it meets the highest standards of strength, durability, and finish. Our quality control processes include non-destructive testing (NDT) and microscopic inspection to detect even the smallest imperfections. | |

4、The company has introduced a number of etching production lines and seamless welding equipment, has a liquid medicine automatic addition system and regeneration system, the development of the company also pay attention to environmental protection, self-built large sewage treatment system, waste water reuse rate of more than 40%, is a rare in the metal etching industry to build a dedicated waterless treatment system of the manufacturer. The company aspires to become an environmental protection enterprise, green enterprise. | |

5、Nantong zhuolida integrates etching and seamless welding, striving for survival, development and efficiency with high precision and standard. | |

6、With shenzhen zhuolida, kunshan zhuolida and nantong zhuolida three production bases, the comprehensive area of more than 40,000 square meters. Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions. The first floor of building 1, zhuolida, nantong is the electrophoresis workshop. The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the requirements of production capacity and precision of various products. The fourth floor is the vacuum diffusion welding workshop. Building 2 is an electroplating industry. | |

01

High precision: High seamless welding precision, small error.

02

Corrosion resistance: Strong corrosion resistance, suitable for a variety of environments.

03

Environmental protection: Reduce material waste and meet environmental standards.

If you want to find a seamless welding factory, please contact us, ZhuoLiDa all staffs will serve you wholeheartedly.