Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

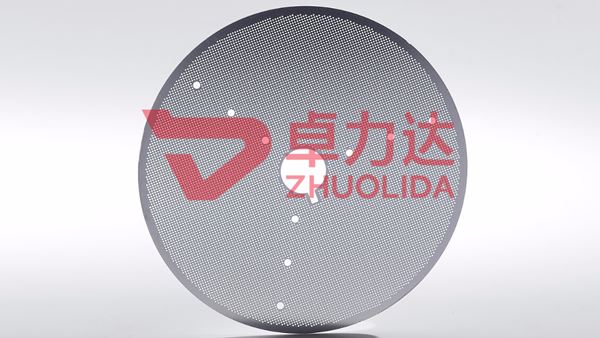

Microporous meshes are widely used in petroleum, chemical, food, juice machine nets, soymilk nets, pharmaceutical precision filters, filter plates, filters; metal leak plates, covers, flat pins for precision electronics and machinery for the electronics industry Flat parts, spring parts, mobile phone parts, etc.

02

Compared with mechanical punching and laser drilling, the quality of the product has the following outstanding characteristics. There are no restrictions on complex patterns and figures with arbitrary geometrical beginnings. No matter how complicated the hole shape or pattern is, it is formed by flash processing without increasing production costs.

03

Chemical etching Microporous mesh is a double-sided simultaneous processing technology. The product surface (front and back) is smooth, no protrusions, no pits, no burrs, no warping, and the mesh is flat and without deformation. No grinding, polishing, self-care process after flattening.。

04

Stainless steel micro-perforated mesh, high precision, no matter how complicated the shape of the product, it can also be batched, low mold opening costs, mold changes of any shape, reduce design and development costs, can achieve half of the metal, add LOGO, brand production Quality and quantity, no pressure point, no deformation of the product, no change in material properties, thick and thin materials can be processed in the same way, to meet different etching production requirements, almost all metals can be etched, there are no restrictions on various pattern designs, and various types of manufacturing Metal parts that cannot be machined.

Nantong Zhuolida is a manufacturer of micro-hole mesh metal etching. The products cover a wide range, covering communication, acoustics, optics, medical, security, machinery, aviation, land vehicles, home appliances, etc. . Processing thickness is from 0.02mm-1.0mm. The opening of the product can reach 0.03mm, and the finer diameter of 0.015mm can reach +/- 0.05mm. If you need micro-hole mesh processing, please contact us. Zolida will be happy to help you.