Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

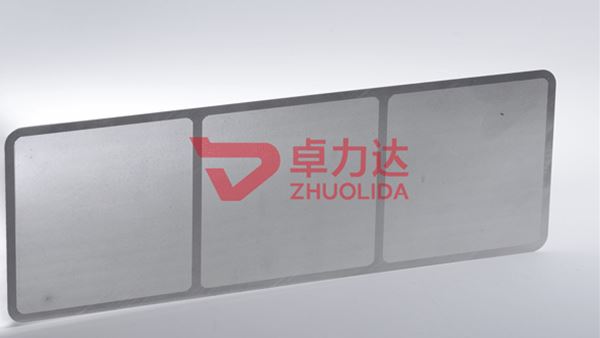

Etching network with direct filtration, simple process, good permeability, uniform and stable precision, no leakage, good regeneration performance, regeneration speed, easy installation, high efficiency, long service life.In air conditioning, purifier, range hood, air filter, and dust collector have been applied.Metal etching mesh has some of the characteristics of metal, such as corrosion resistance, strength, impact.At the same time, the metal etching mesh through the control of mesh density, material thickness can adjust the filtering accuracy, and easy to clean, easy to replace and maintenance.

02

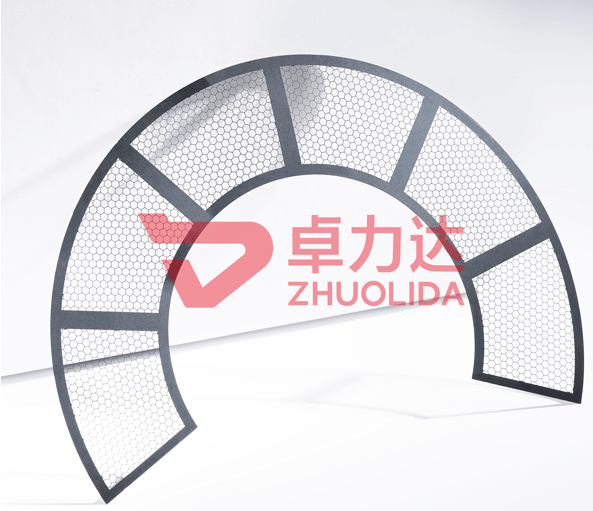

Etching mesh products can adapt to a variety of complex shapes and patterns, high precision.The handicraft that etch net makes not only modelling is beautiful and easy, the structure is lightsome, suit household decoration especially, resemble the wall painting that etch net makes, hollow-out etch net vase, show its luxuriant honour all the time.

03

Etch screen metal etching technology improves the traditional metal processing methods.This metal etching technique can be used to process concave-convex metal products through data, design and complex columns.Etching techniques can be used to make holes and various forms.The bubbles generated during the etching chemical reaction often cause the inhomogeneity of the etching. The retention of the bubbles on the substrate prevents the etching solution from contacting the surface of the etched object, which slows down or stops the etching rate until the bubbles leave the surface of the substrate.In this case, a catalyst is added to the solution to increase the contact between the etch solution and the surface to be etched, and it is agitated during the etching process to accelerate the removal of bubbles.

04

The hole opening rate of the etched network determines the precision of the product. The higher the hole opening rate, the higher the precision requirement of the relative hole will be.Zolida stable high precision equipment for us to provide good quality and production capacity.

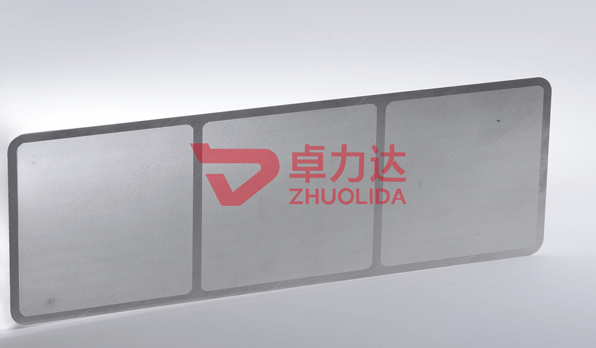

Zhuo li da can use the volume to volume exposure machine, can be mass production, the production of up to 1000 square meters per day, for small batch diversification of the etching network, can also be semi-automatic production, to save related operating costs, to save costs for customers is our goal, to achieve a win-win situation.We produce the etching net without burr, pressure point, product deformation, do not change the material properties, do not affect the product function.If you want to find etching network manufacturers, please contact us, zhuolida staff will be dedicated to serve you.