Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

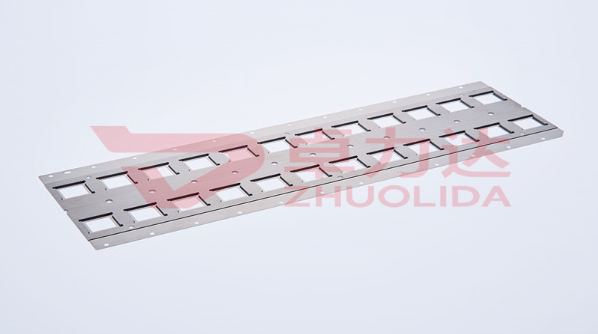

A coating fixture is a two-sided sputtering device for quartz crystals or wafers, also known as a mask fixture, which includes a vacuum chamber, a vacuum pumping unit, a workpiece holder, a magnetron sputtering target, a rf plasma cleaner, and an inert gas inflator

02

The coating fixture usually has a combined thickness of more than 1.0mm, with Chambers of different shapes and depths on both sides. The fabrication is usually layered etching, and then bonded together by vacuum diffusion welding, so that a finished product is completed.

Our company can manufacture all kinds of coating jig, linear fine adjustment plate, mask jig, automatic dispensing plate, automatic sealing plate and other special equipment. The company's products are all imported materials and precision manufacturing process, and according to the customer's specifications, requirements, design and manufacture of related products. Up to now, our company can complete more than 80,000 sets of various coating fixture products every year. We have two precision metal etching factories and a vacuum diffusion welding base to undertake the etching processing and vacuum diffusion welding processing business of various coating fixture. If you want to find a crystal coating fixture manufacturers, please contact us zhuolida, zhuolida staff will be dedicated to serve you.