Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

01

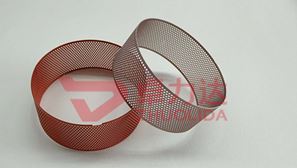

Microporous plate etching and a variety of small hole processing products have been widely used in the precision filter equipment, jet engine nozzle, printed circuit board, astrology star hole plate, aviation gyroscope instrument components, aircraft turbine blades and medical equipment in the red blood cell filter processing parts.Zolida USES chemical etching process to process some mesh dense, high tolerance requirements of microporous plate etching processing has a very unique processing method.The hole wall after processing is hairless, with uniform pore diameter and good roundness.

02

Precision detection of secondary element and imaging instrument, 24-hour service hotline 0513-81601666. We are a precision etching factory and are responsible for the after-sales service of all our microporous plate etching products.Whether it is service attitude, or product quality, communication about product design, sales quality of service, can be directly communicated.The factory has a superb quality control team, the rapid response mechanism, for customer complaints, within 24 hours to reply.Propose corrective measures within 48 hours and deliver qualified products within 3 days.

The microporous plate etching products produced by our company can ensure the extremely high precision, the precision can reach +/-0.01mm, and the processing quality is stable, the batch is clear, the quality control system is strict.Microplate etching can meet the precise assembly requirements of different components and improve the quality and precision of the whole product.With the service concept of precision, timeliness, convenience and environmental protection, the company has fast manufacturing, quick distribution system and emergency service team to serve every new and old customer.