Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product introduction | |

Product name: | |

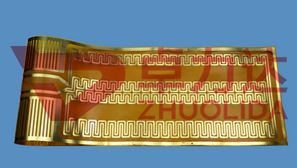

Product description: | VC homogenizing plate (Vapor Chamber) is similar to heat pipe in technical principle, but different in conduction mode.The heat pipe is one-dimensional linear heat conduction, while the heat in the vacuum cavity plate is conducted on a two-dimensional surface, so the efficiency is higher. |

Product usage: | VC board is usually used for small size or need to quickly dissipate high heat electronic products.At present, it is mainly used in servers, high-end graphics CARDS and other products, and is a strong competitor of heat pipe cooling. |

Etching process: | Material opening → cleaning plate → dry film or coating → drying → exposure → development → drying → etching → stripping → detection of packaging -- finished product shipment. |

Our strengths | |

1. Till 2018, we have been engaged in the field of etching for 19 years. In 2015, the company invested in the construction of a new industrial park in nantong.Aspire to become China's etching industry hundred year enterprise! | |

2. The company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the company has passed ISO/TS 16949 certification and high-tech enterprise certification, and has obtained multiple property rights and patents.Zolida has been focusing on technology research and development, with a professional laboratory and external employment and training of high-tech talents, is a benchmark enterprise in the industry. | |

3. The company is a member of PCMI, an organization of the world etching association, and can share the information and equipment of the global VC average temperature board. | |

4. Several etching production lines have been introduced, and the company has an automatic adding system and regeneration system for potions. While developing, the company also pays attention to environmental protection.The company aspires to become an environmental protection enterprise, green enterprise. | |

5. At present, materials of VC temperature plate are 0.10mm, 0.12mm, 0.15mm, 0.2mm, etc., with precision tolerance up to +/-0.01mm, surface passivation and anti-oxidation treatment. | |

6. Shenzhen zhuolida, kunshan zhuolida and nantong zhuolida three production bases, with a comprehensive area of more than 40,000 square meters.Nantong has built an industrial park, which involves etching, electroplating electrophoresis, anodic oxidation, laser welding, vacuum diffusion welding and other fields, providing customers with integrated solutions.The first floor of building 1, zhuolida, nantong is the electrophoresis workshop.The second and third floors are etching workshops, with more than 20 conventional, imported and customized non-standard precision etching lines, which can meet the requirements of production capacity and precision of various products.The fourth floor is the vacuum diffusion welding workshop.Building 2 is an electroplating industry. | |

01

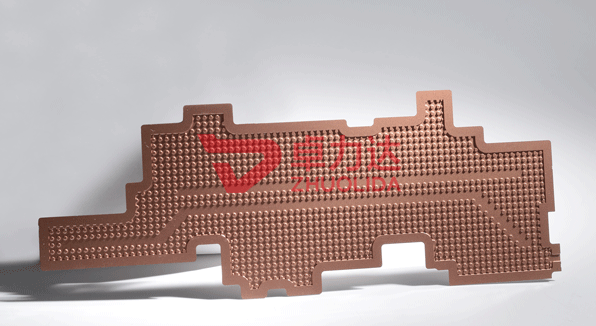

VC equalizing plate is a kind of flat heat pipe, which can transfer the heat flow gathered on the surface of the heat source rapidly and diffuse to the large area of the condensation surface, thus promoting the heat emission and reducing the heat flux density on the surface of components.

02

Structure of VC equal-temperature plate: it is composed of the bottom plate, the frame and the cover plate to form a completely closed flat cavity. The inner wall of the cavity is provided with a liquid absorption capillary core structure. The capillary core structure can be wire mesh, micro-groove, fiber wire, or metal powder sintered core and several structure combinations.When necessary, a supporting structure should be provided inside the cavity to overcome the deformation caused by the negative pressure of vacuum pumping and the external expansion caused by heat.

03

Advantages of VC board: small volume can make the radiator control to the entry level low power consumption as thin;It conducts heat quickly and is less likely to lead to heat accumulation.The shape is not limited, can be square, round, etc., to adapt to various cooling environment.Low starting temperature;Fast heat transfer rate;Good temperature equalization performance;High output power;Low manufacturing costs;Long service life;Light weight.

04

Application of VC temperature equalizing plate in computer field: most of VC temperature equalizing plates are customized products, which are suitable for electronic products requiring small volume or rapid heat dissipation. At present, it is mainly used in servers, tablet computers, high-grade graphics cards and other products. In the future, it can also be used in the heat dissipation of high-level telecommunication equipment, high-power LED lighting, etc.

Nantong zhuolida has an independent business division of VC uniform temperature plate and special equipment for uniform temperature plate etching, specializing in a variety of uniform temperature plate etching processing business, and a number of well-known heat pipe manufacturers and communication manufacturers to provide free VC uniform temperature plate process solutions.If you need to do VC board products, or you need to understand the process and principle of VC board, please contact us, we will serve you wholeheartedly!0513-81601668.