Product

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

HOTLINE

86-513-81601668 86-18206293159

86-513-81601668 86-18206293159

Product introduction | |

Product name: | The corrosion process |

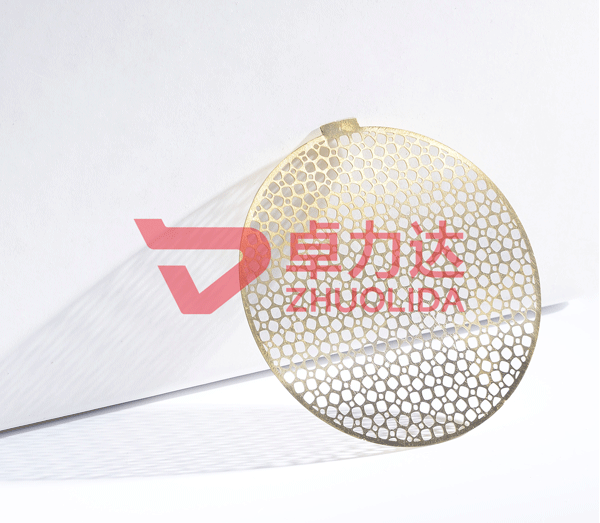

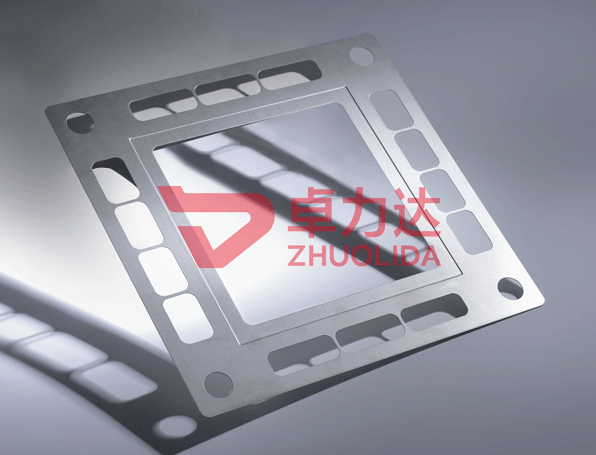

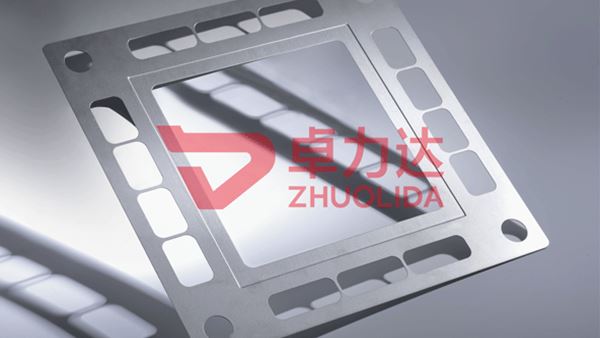

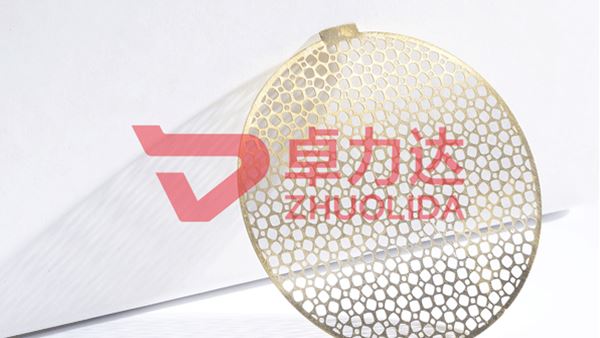

Product description: | Corrosion processing is a popular word for etching. The commonly referred to etching is also called photochemical etching. It refers to the removal of the protective film of the etching area through exposure to plate making and development. |

Samples provided: | Paid sample making, samples within 3 days, can be 24 hours, you can apply for free for special samples.Under normal circumstances, we need to charge for samples.The main reason is to charge basic template fees and labor, water and electricity, and plant rent in the etching process.The etching process itself, due to its fast reaction time and relatively low cost, has saved a lot of costs for related design and manufacturing.As many as 100 kinds of new products need proofing every month, so the cost pressure is huge.In the spirit of win-win and mutual benefit, the majority of customers in the communication also expressed understanding. |

After test: | Precision detection of secondary element and imaging instrument, 24-hour service hotline 0513-81601666. We are a precision etching factory and are responsible for all our products after sales.Whether it is service attitude, or product quality, communication about product design, sales quality of service, can be directly communicated.The factory has a superb quality control team, the rapid response mechanism, for customer complaints, within 24 hours to reply.Propose corrective measures within 48 hours and deliver qualified products within 3 days. |

Our strengths | |

1. Till 2018, we have been engaged in the field of etching for 19 years, and have been committed to the innovation, research and development, production and sales of corrosion processing technology in the middle and high-end market.Aspire to become China's etching industry hundred year enterprise! | |

2. The company has successively passed iso9001:2008 quality management certification and iso14001:2004 environmental management system. In 2016, the company passed ISO/TS 16949 certification and high-tech enterprise certification. | |

3. As a member of PCMI, the world etching association, the company can share new information and equipment of the global etching industry. | |

4. It has an automatic adding system and regeneration system for potions, and a self-built large-scale sewage treatment system, with the reuse rate of wastewater reaching above 40%. | |

5. We can do corrosion machining with a thickness of 0.02mm and an etching size of 800*70mm, with a precision up to +/-0.005mm according to the product. | |

6. Shenzhen zhulida, kunshan zhulida and nantong zhulida three production bases, with a comprehensive area of more than 40,000 square meters.More than 20 conventional, imported and customized non-standard precision etching lines can meet the requirements of productivity and accuracy of various corrosion processing. | |

01

Corrosion processing process generally includes: according to customer drawings computer design and production of film, cleaning, printing drying, exposure development, etching, cleaning and drying.

02

Corrosion processing can be used to process arbitrary cutting metal materials, not limited by hardness, strength and other properties.Etching can produce thin metal parts quickly and cheaply.The products processed by corrosion have no burr, no bulge, the same light and the same flat on both sides;The production process has no external impact, no deformation, good flatness;And the production cycle is short, the strain is fast, does not need the mold design, the manufacture;And long life, the whole network by a flat plate manufacturing.

03

Corrosion processing is widely used, especially in the field of electronics. Due to the development of science and technology, products are required to have smaller and more detailed space. It is difficult for traditional machining to meet the demand.

04

Corrosion machining can achieve the metal half engraving, this process can be used in the production of trademarks, identification codes, and line, pattern production.The outstanding characteristics of each process are different according to the choice of the customer.The choice of different processes can achieve the desired effect of the customer.