News

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

As design specifications become smaller, power density increases significantly at all packaging levels.The heat dissipation from the equal-temperature plate is very important for the normal operation and long-term stability of electronic equipment, and whether the temperature of components is maintained within the specification range has become a general standard to determine the acceptability of design.

The cooling plate solution directly increases the weight, volume, and cost of the product without any functional advantage.They provide reliability.Without a cooling solution, many electronics can break down in minutes.The leakage current and the subsequent leakage power consumption increase with the reduction of the chip level characteristic size.Because leakage is temperature dependent, thermal design is even more important.Then what role does the uniform plate play in the heat dissipation of electronic products?

As a heat transfer element, the equal-temperature plate can provide the heat dissipation demand of the electronic industry and many other industries.

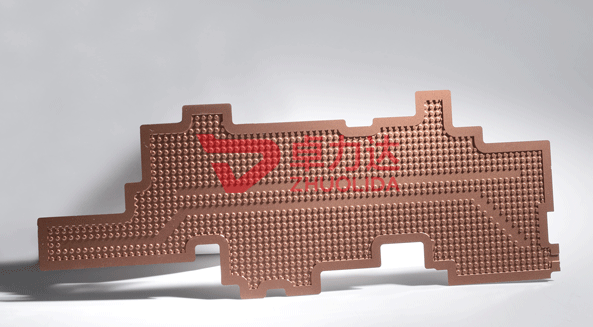

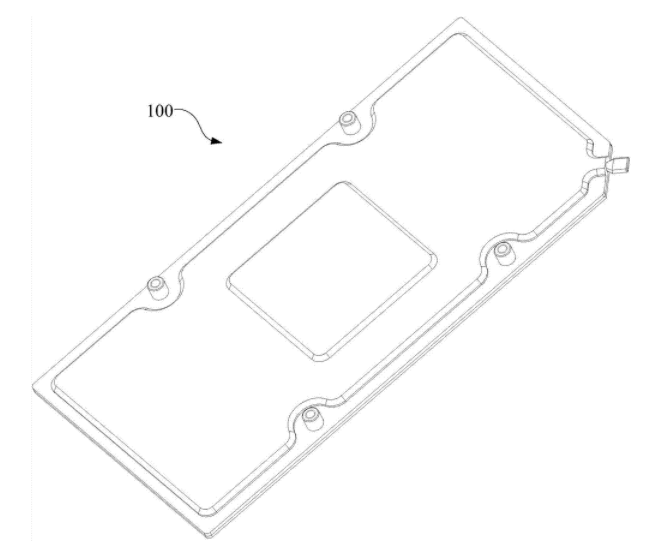

The uniform temperature plate, also known as the uniform temperature plate, is a vacuum chamber with fine inner wall structure. It has the following performance advantages:

1. Strong thermal conductivity: thermal conductivity up to 3000 ~ 10000W/(m•K);

2. High heat dissipation power: change the heat dissipation area to change the heat dissipation problem of local high heat flux;

3. Good temperature homogenization performance: temperature difference is less than 5℃;

4, strong structural adaptation: the shape is not limited, can be square, round, etc., to adapt to a variety of heat dissipation environment.

Operation details:

1, heating plate base, heat source heating copper grid micro-evaporator -- heat absorption

2. The coolant (pure water or refrigerant) can be rapidly vaporized into hot air (<104 Tor or less) under vacuum and low pressure

3, hot air in the copper mesh microenvironment circulation faster - heat conduction

4. Hot air rises when heated, dissipates heat after meeting the cooling source on the upper part of the cooling plate, and recondenses into liquid -- dissipates heat

5. The condensed coolant is returned to the source of steaming at the bottom of the plate through the capillary channel of copper microstructures -- backflow. The backflow coolant is re-gasified after being heated through the evaporator and dissipates heat through the copper mesh microtube heat absorption >, thermal conduction >, and so on.

Zolida has a number of imported etching processing lines, and a number of the world's top 500 enterprises to provide free solutions to the plate technology.Hotline: 0513-81601668.