News

FRIENDLY/link Nantong zhuolida Ali SAMSAN Corrosion machining Nantong zhuolida HJD Shenzhen zhuolida Esprit print

A brief introduction to the differences among stainless steel etching, copper etching and aluminum etching

In the process of etching, customers will meet a variety of material needs.Such as stainless steel, aluminum and copper alloys.Here briefly describes the stainless steel etching, copper etching, aluminum etching three differences.

Stainless steel etching: stainless steel is different from copper or aluminum alloy, it is not easy to oxidize in the air, so it does not need to be passivated after cleaning, which makes the pretreatment process of stainless steel much simpler than copper and aluminum alloy.At the same time, the stability of stainless steel in alkaline solution is relatively high, so you can use a strong alkaline solution for surface treatment, of course, can also use acid cleaning agent to clean.Stainless steel etching method has immersion etching method and spray method, if the product etching depth requirements, you can choose spray method;Conversely, if the product etching depth is not high, you can choose the immersion method.

Stainless steel etching solution has two formulations, by the vast majority of etching plant to use iron trichloride mainly etching solution, and then according to the need to add some can increase the etching performance of the added substances, such as nitrate, phosphoric acid, hydrochloric acid, sulfur, benzodiazepine oh, ullotopine, lorate, etc.;(2) the use of nitric acid, hydrochloric acid, phosphoric acid preparation of water etching solution, this etching solution prepared after the need to use mild steel to aging, and then through the analysis of the adjustment to the process concentration range.

Copper etching: copper etching and stainless steel potions can be general etching, copper element is more active than iron, copper can restore iron ions, so etching copper is not cost the potion;Fade ink is also a strong base, but copper is easy to oxidize, after the need to reduce the color.So copper etching process is more complicated than stainless steel process;The choice of copper and alloy etching solution has a large degree of freedom, the commonly used etching system is three iron sulfide etching system, acidic copper chloride etching system, alkaline copper sulfide etching system, sulfuric acid hydrogen peroxide etching system, the use of more iron sulfide etching system and alkaline copper chloride etching system.In these etching systems, the solution of sulfuric acid-hydrogen peroxide etching system is easy to be regenerated, and the copper in the etching solution is easy to be recovered.Although ferric chloride etching system has high environmental pollution, it is easy to prepare, low cost and easy to manage, so it is widely used.In the actual production of iron trichloride etching system is also used a lot of methods

Aluminum etching:Aluminum etching need liquid proportion is lower, it reacts with liquid medicine is very severe, will release a large amount of heat, low proportion can slow down the process of reaction, low etch aluminum liquid medicine proportion reduction of little value, so the basic waste liquid discharge, so the etching aluminium cost potion is bigger, is produced sewage, aluminum faded ink needs with nitric acid, hydrofluoric acid, etc., nitric acid smell of smoke is bigger, hydrofluoric acid with poisonous, so the process is relatively complicated.

The etching system of aluminum alloy has acid and alkali, acid etching system is more use of ferric chloride, hydrochloric acid, also use phosphoric acid fluoride system.Among them, ferric chloride etching system is commonly used.The etching quality of alkaline etching is better than that of ferric chloride, and the etching cost is low, which is a better etching method. However, the production cost of corrosion prevention layer of alkaline etching is higher than that of acid etching, which is the bottleneck restricting the extensive promotion and application of alkaline etching at present.

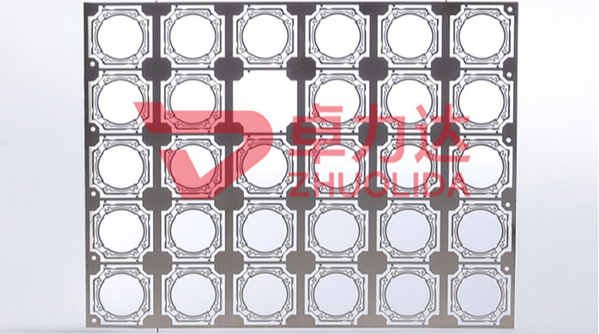

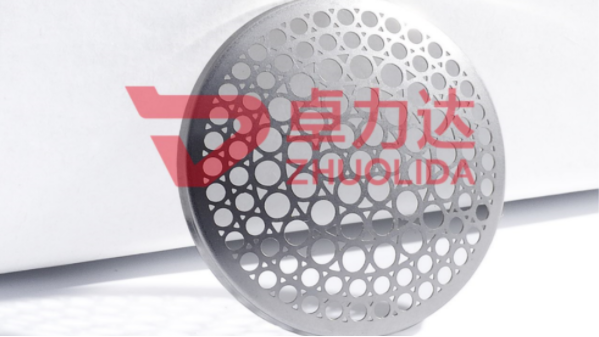

Nantong zhuolida metal technology co., ltd. is a high-tech enterprise engaged in the research and development and production of precision metal etching and SMT laser template, and vacuum diffusion welding.The introduction of a number of etching production lines, in stainless steel, aluminum alloy and copper etching have rich experience, welcome to inquire!